Ventilated Plastic Enclosure for Heat Control

- group name

- Custom Plastic Enclosure

- Min Order

- 2000 piece

- brand name

- FromRubber Silicone & Plastic OEM Manufacturer

- Nearest port for product export

- FOB shenzhen

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, FCA, DDP, Express Delivery

- Acceptable payment methods

- T/T, D/P D/A, Credit Card, PayPal, Westem Union, Cash

- update time

- Fri, 06 Mar 2026 08:07:31 GMT

Paramtents

Design Follow 3D Drawing Or Physical Object

Process Molding

Feature Low-resistance

MOQ 2000pcs

Application industrial, medical & automotive applications

Packging & Delivery

-

Min Order2000 piece

Briefing

Detailed

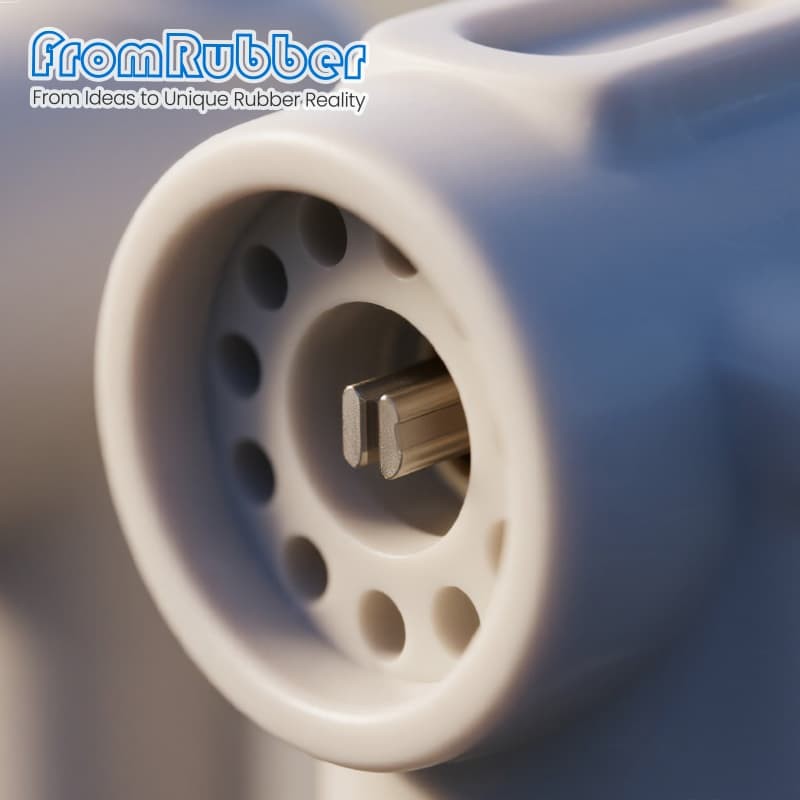

Efficient Passive Ventilation Design

Designed with precision-cut air vents, this plastic enclosure allows continuous airflow over internal components, effectively dissipating heat without the need for fans or heat sinks.

The vent geometry and placement are customizable to optimize thermal convection, especially for power-intensive applications like chargers, converters, and control boards.

Choose from horizontal slits, honeycomb vents, or mesh patterns for maximum performance and aesthetic integration.

Applications Across Industries

Ideal for electronics requiring thermal stability during continuous operation:

- Power Modules – AC/DC adapters, inverters

- Communication Devices – routers, hubs, signal amplifiers

- Lab Instruments – temperature-sensitive control panels

- Battery Management Systems (BMS)

- Embedded Control Units – industrial, automotive, medical

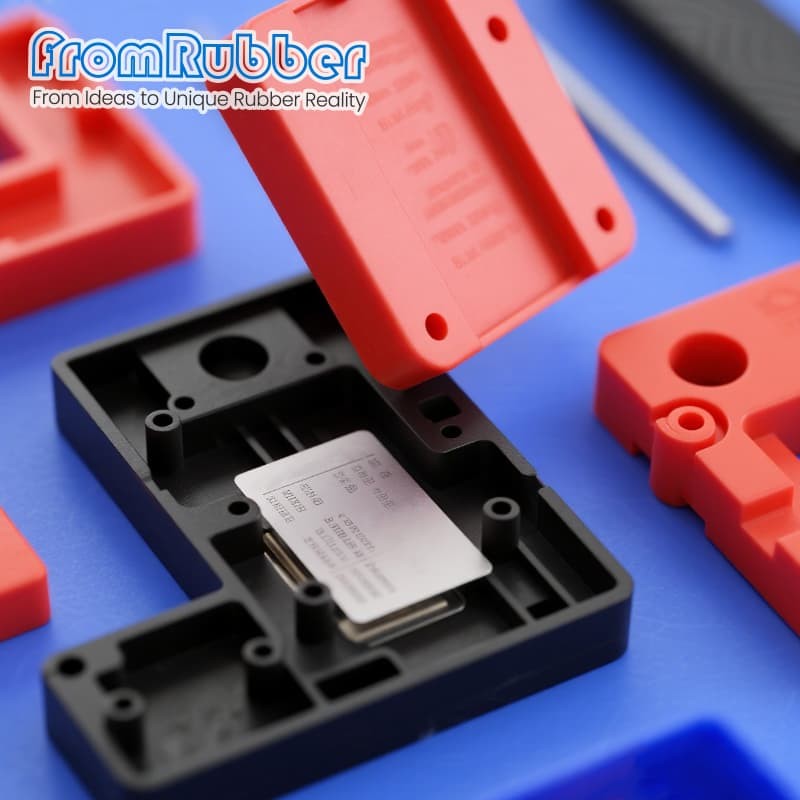

Structural Customization & Material Options

Every enclosure can be tailored to your device’s power output and thermal profile. We provide:

- Vent positioning based on thermal simulation

- Snap-fit or screw-mount assembly structures

- Design assistance for airflow channeling and shielding

- Material choices: flame-retardant ABS, PC, PC+ABS blends

- Surface options: textured, matte, electroplated, or painted

Technical Specifications

| Material Options | ABS / PC / PC+ABS / FR-rated blends |

|---|---|

| Ventilation Style | Slotted / Grid / Honeycomb / Custom |

| Wall Thickness | 1.5 – 3.0 mm |

| Assembly Method | Snap fit / Screw lock / Ultrasonic welding |

| Color Options | Standard black / white / Pantone customization |

| MOQ | 2000 pcs |

Frequently Asked Questions

A: Yes, we can run thermal simulations and adjust the enclosure design to direct airflow over your main heat-generating components.

A: With proper material selection (e.g., UV-resistant PC) and water-deflecting vent designs, we can adapt the enclosure for outdoor use.

A: Absolutely. We offer UL94-V0 or higher grade materials for enhanced safety in high-power applications.