Custom Silicone Button Customization with OEM ODM Options

- group name

- Custom Silicone Rubber Meter Instrument Keypad

- Min Order

- 1 piece

- brand name

- FromRubber Silicone & Plastic OEM Manufacturer

- model

- BH-silicone button

- Nearest port for product export

- FOB shenzhen

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, FCA, DDP, Express Delivery

- Acceptable payment methods

- T/T, D/P D/A, Credit Card, PayPal, Westem Union, Cash

- update time

- Wed, 04 Mar 2026 22:41:37 GMT

Paramtents

Product Name Silicone Buttons

Hardness 30A-80A

Color Custom

Process compress+printing+laser etching+packing

Quantity According to your needs, 1pc is also available

Application Mechanical equipment

Features Durable, waterproof, good feel

Package On request

Packging & Delivery

-

Min Order1 piece

Briefing

Detailed

Silicone Button Customization Guide

1. Product Overview

Silicone button customization offers a flexible and reliable way to create control interfaces for a wide range of devices. Whether you need custom silicone push buttons, printed silicone buttons, or backlit silicone push buttons, these components combine durability, comfort, and design versatility. Silicone is valued for its soft yet resilient texture, excellent resistance to wear, and ability to perform in demanding environments.

In electronics and devices, silicone buttons are ideal because they provide:

- Excellent tactile feedback for consistent user experience

- Waterproof and dustproof capabilities for outdoor or heavy-use equipment

- Long lifespan withstanding thousands to millions of actuations

- Compatibility with backlighting for improved visibility in low-light conditions

As a specialized OEM/ODM silicone rubber button manufacturer, we offer complete silicone button molding services—from concept design to mass production. Our factory produces everything from custom rubber keypads for consumer electronics to silicone dome switches for industrial equipment. With advanced manufacturing capabilities and Pantone color matching, custom textures, and logo printing, we deliver silicone rubber tactile buttons tailored to your exact specifications.

2. Customization Capabilities

We make silicone button customization simple and flexible, so your product works exactly how you want it. Every detail—size, shape, color, and feel—can be tailored to fit your design and brand requirements.

2.1 Size and Shape

We offer versatile molding options to match your exact product specs. Whether you need small tactile switches or large control pads, we can create the perfect fit.

2.2 Color Customization

- Pantone matching for precise colors

- Multi-color solutions for layered or segmented designs

- Translucent buttons for backlit or indicator use

2.3 Surface Texture and Finish

Choose the texture to match your product’s style and user comfort:

- Smooth

- Matte

- Glossy

- Anti-slip

2.4 Logo and Artwork Printing

We can brand your custom silicone push buttons using:

- Pad printing

- Embossing

- Debossing

- UV printing for durability and sharp detail

2.5 Backlighting Options

We integrate LED backlighting for easy visibility in low-light environments, perfect for remote controls, automotive dashboards, and industrial gear.

2.6 Tactile Response

We adjust hardness levels and dome designs to get the right feedback—soft press, firm click, or something in between.

2.7 Additional Features

- Waterproofing for outdoor or heavy-use applications

- Chemical resistance for industrial settings

- Wear resistance coatings to extend button lifespan

| Feature | Options Available |

|---|---|

| Size & Shape | Custom mold to your specs |

| Color | Pantone match, multi-color, translucent |

| Finish | Smooth, matte, glossy, anti-slip |

| Branding | Pad print, emboss, deboss, UV printing |

| Backlighting | LED integration |

| Tactile Feel | Adjustable hardness & dome shape |

| Protection | Waterproof, chemical & wear resistance |

3. Material and Quality Specifications

We use high quality food grade and industrial silicone rubber for all our custom silicone push buttons. For consumer electronics, wearables, and toys, we offer non-toxic food grade silicone. For industrial and automotive controls, we use high-durability industrial silicone rubber that can handle tough environments.

3.1 Compliance and Safety

Our materials meet strict U.S. and international safety and environmental standards:

| Standard | Purpose | Applicable Use |

|---|---|---|

| RoHS | Limits hazardous substances | Electronics, automotive |

| REACH | Regulates chemical safety | All silicone button applications |

| FDA | Food contact safety | Food service, medical devices |

3.2 Tested Durability

We run performance simulations to make sure our silicone rubber buttons last through heavy use.

- Abrasion resistance – Keeps the surface looking new even with frequent pressing.

- Actuation cycles – Designed to withstand 500,000+ presses without losing feel.

- Temperature stability – Works reliably in both hot and cold conditions.

- UV and chemical resistance – Protects against fading and damage in outdoor or harsh applications.

We focus on giving you silicone rubber tactile buttons that are safe, compliant, and built to outlast your product—whether it’s a medical keypad, a game controller, or a piece of industrial machinery.

4. Manufacturing Process

When we make custom silicone buttons, we follow a clear and efficient process from start to finish. Our goal is to deliver consistent quality whether you need a single prototype or a large production run.

4.1 From Prototyping to Mass Production

We start with your design files or drawings, then create a prototype so you can test the size, feel, and fit. Once approved, we move into full production using advanced silicone molding methods. This step-by-step approach ensures the final product matches your exact specifications before we scale up production.

4.2 Advanced CNC Machining and Silicone Injection Molding

For molds, we use precision CNC machining to achieve accurate button shapes and tight tolerances. Our silicone injection molding equipment handles both simple and complex designs, including translucent buttons, multi-color layouts, and integrated backlighting.

4.3 Quality Control at Every Stage

We run strict quality checks during every step:

- Material inspection before production to confirm grade and compliance (RoHS, REACH, FDA where needed)

- Dimensional checks on samples from each batch

- Tactile feedback testing for consistent button response

- Durability tests for wear resistance and actuation cycles

This layered process helps us deliver OEM and ODM silicone buttons that are reliable, consistent, and ready for everyday use in electronics, automotive, medical devices, and more.

5. Lead Times and Order Quantities

We know timing matters when it comes to silicone button customization, whether you're testing a new design or gearing up for national distribution. Our lead times are built to fit different project needs:

- Prototypes – Most sample runs are ready in 3-5 business days after design approval.

- Small to mid-size orders – Typically ship within 1-2 weeks, depending on complexity.

- High-volume production – For large OEM runs, lead time is usually 2-3 weeks, with priority scheduling available for urgent projects.

Our minimum order quantity (MOQ) starts at 1 pcs for custom silicone push buttons. We scale easily for large runs, with the capacity to handle hundreds of thousands of units without delays.

6. Applications and Use Cases for Silicone Button Customization

6.1 Consumer Electronics

Custom silicone push buttons are widely used in TV remotes, media players, game controllers, and smart home devices. Their durability, tactile feel, and customizable shapes make them the go-to choice for brands aiming for both style and comfort in daily-use gadgets.

6.2 Medical Devices

In healthcare, personalized silicone keypad overlays are ideal for medical monitors, diagnostic tools, and control panels. They’re easy to clean, meet strict hygiene standards, and can be made with FDA-compliant silicone for patient safety.

6.3 Automotive

From dashboard controls to steering wheel push buttons, silicone is a top pick in cars and trucks. It stands up to constant use, temperature changes, and UV exposure, all while supporting backlit silicone push buttons for night driving.

6.4 Industrial Equipment

Silicone rubber tactile buttons are common in machinery keypads and rugged control panels. They handle heavy use, resist industrial chemicals, and can include anti-slip textures for gloved operation.

6.5 Wearable Technology and Custom Gadgets

For smartwatches, fitness trackers, and specialty gadgets, translucent buttons and custom rubber keypads allow sleek designs without sacrificing function. Silicone molding makes it easy to match brand colors and integrate compact layouts for small devices.

7. Why Choose FromRubber

When it comes to silicone button customization, we know customers expect quality, speed, and reliability. FromRubber has built a reputation over decades as a trusted silicone rubber button manufacturer for industries ranging from electronics to automotive.

7.1 What Sets Us Apart

| Feature | Benefit to You |

|---|---|

| Decades of Experience | Proven track record in producing custom silicone push buttons, OEM silicone keypad buttons, and silicone dome switches for leading brands. |

| State-of-the-Art Facilities | Advanced CNC and silicone injection equipment for precise molding, color matching, and backlit button integration. |

| Dedicated R&D | In-house team developing new textures, finishes, and tactile designs to keep your products competitive. |

| Competitive Pricing | Efficient processes keep costs low without cutting quality. |

| Global Shipping | Reliable logistics to deliver anywhere in the U.S. on time. |

| Exceptional Support | U.S.-friendly communication, fast response, and technical guidance from concept to delivery. |

We combine modern production capability with hands-on service that understands local market demands—whether you need personalized silicone keypad overlays, silicone rubber tactile buttons, or high-volume silicone keypad button supply. Every order, big or small, gets the same attention to detail and strict quality control.

8. Ordering Process for Silicone Button Customization

Getting your custom silicone buttons made is simple. We keep the process clear so you can move from idea to production without delays.

8.1 How to Submit Your Design or Request Samples

- Send us your button pad design files (STEP/STP format ) via email.

- Not ready with final designs? Share your concept, and we’ll help refine it.

- Need to feel the quality first? Request sample silicone buttons or similar OEM projects we've done.

8.2 Consultation for Design Optimization

Our team will review your project and suggest:

- The best molding method for your shape and size

- Ideal material hardness for your tactile needs

- Recommended printing and color matching options

- Any durability upgrades like waterproofing or wear-resistant coating

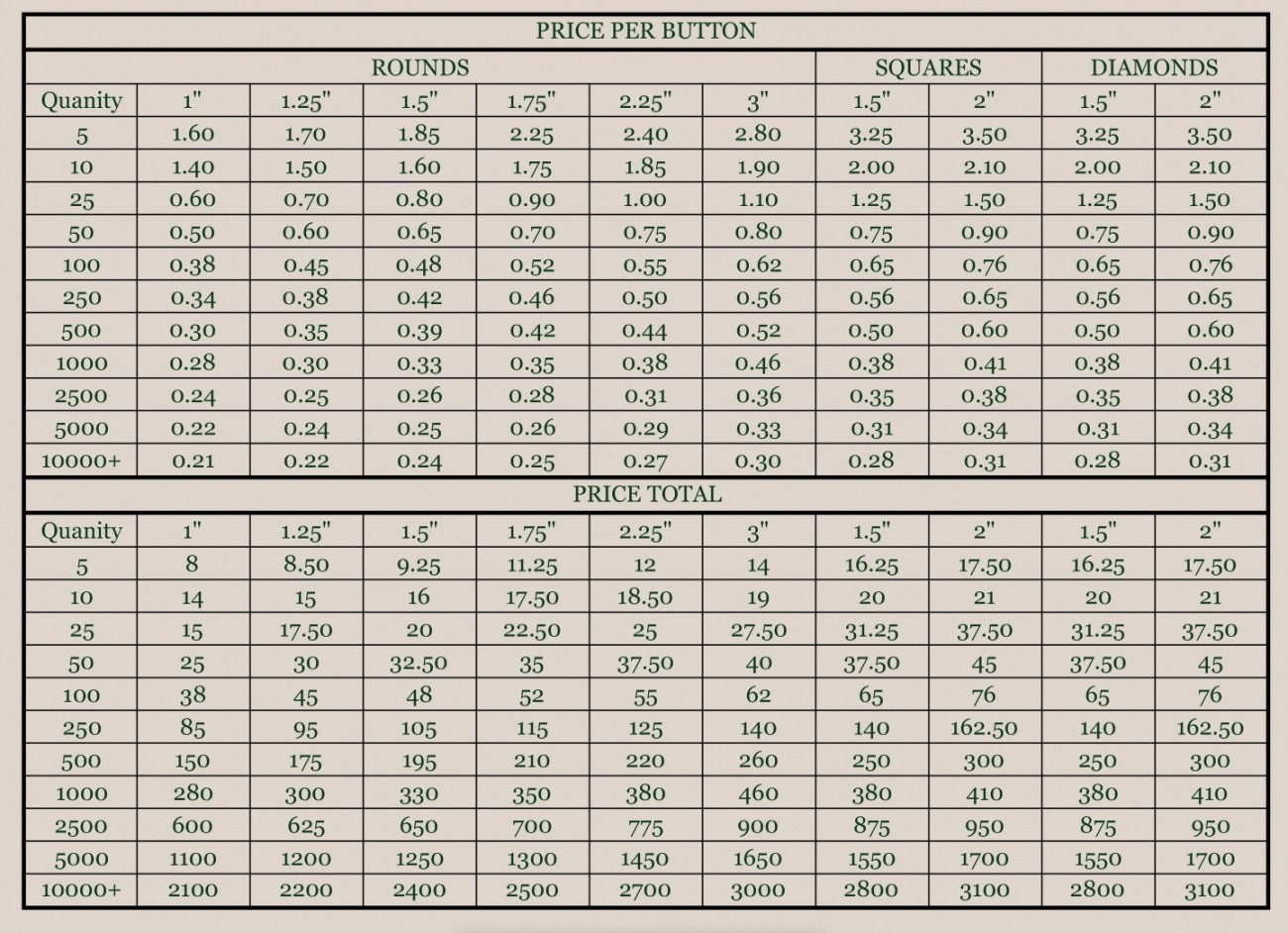

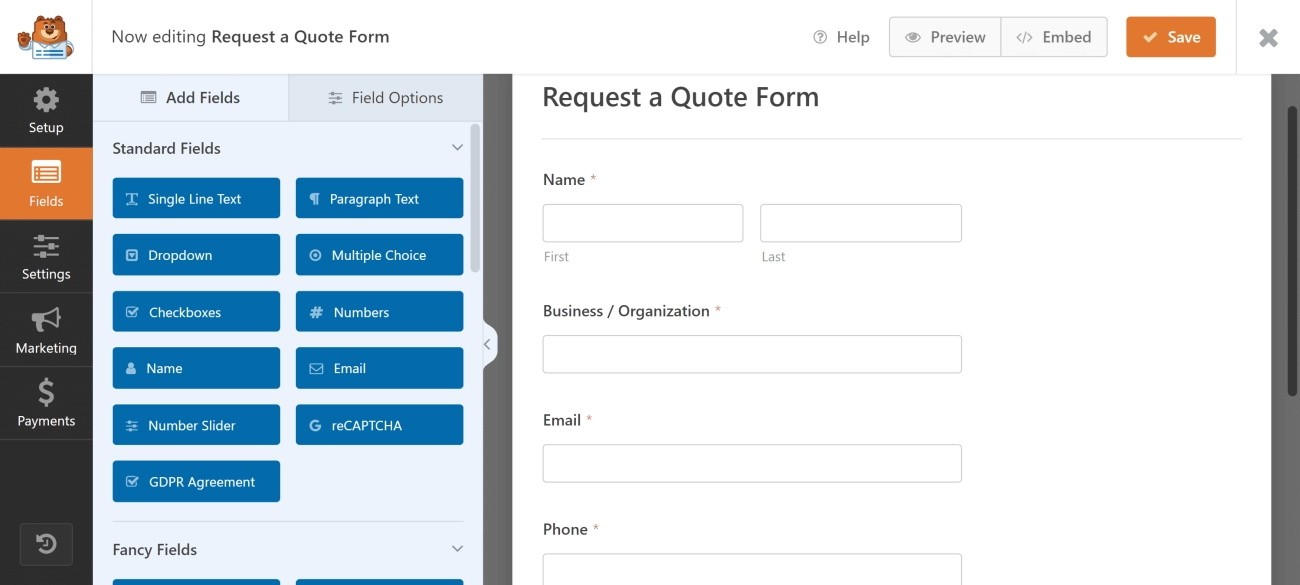

8.3 Getting a Quote

- Fill out our quote request form with size, quantity, and special features (e.g., backlighting, logo printing).

- We’ll reply quickly with pricing, lead time, and MOQ details.

- For large runs, we can provide cost breakdowns and scaling options.

Contact us directly by phone or email—our U.S. support team can walk you through the process and help you choose the right silicone button customization solution for your product.

9. FAQs for Silicone Button Customization

Here are answers to the most common questions we get from U.S. customers about custom silicone push buttons, materials, printing, and durability.

9.1 What materials do you use?

We work with high-quality silicone rubber — both food-grade and industrial-grade options. All materials can be compliant with RoHS, REACH, and FDA standards when needed.

9.2 Can you match my brand color?

Yes. We use Pantone color matching to hit your exact shade, including solid, translucent, or multi-color designs.

9.3 What printing methods are available?

We offer:

- Pad printing – for simple and cost-effective graphics

- Silk screen printing – for bold colors and larger designs

- UV printing – for detailed, full-color images

- Embossing/Debossing – for raised or recessed effects that last

9.4 Are backlit silicone buttons possible?

Yes. We can integrate LED backlighting with translucent or laser-etched buttons for night-time visibility.

9.5 How durable are the buttons?

Typical performance:

| Feature | Performance Range* |

|---|---|

| Actuation cycles | 500,000 – 1,000,000 presses |

| Operating temperature range | -40°F to 392°F |

| Wear resistance | High (tested against abrasion) |

| Waterproofing | Up to IP67 rating available |

*Varies by design and material specification.

9.6 Do the buttons resist chemicals or weather?

Yes, we can add coatings for waterproofing, chemical resistance, and UV stability for outdoor or harsh environments.

9.7 Can you adjust the feel or feedback?

Yes. We control silicone hardness (shore rating) and dome switch design to deliver light, medium, or firm tactile response.

9.8 What’s the smallest order I can place?

Our MOQ depends on size and complexity. Prototypes usually start at low quantities, while bulk production can scale to thousands.

9.9 How do I send my design?

You can email CAD files, drawings, or even a physical sample for custom silicone button molding. We also offer design assistance if you need help optimizing your layout.

10. Customer Testimonials and Case Studies

Here’s a look at how our silicone button customization has helped different industries get exactly what they need.

10.1 Real-world Projects

- A U.S. medical device company came to us for personalized silicone keypad overlays with color-coded functions for quick identification in emergency situations. We delivered OEM silicone keypad buttons with FDA-compliant materials and laser-etched markings that stay clear after thousands of cleanings.

- An automotive electronics supplier partnered with us to create backlit silicone push buttons for dashboard controls. Our precise molding and LED integration gave them long-lasting illumination and a premium feel.

- A gaming accessories brand used our silicone dome switches customization for a new controller design. We tuned tactile feedback and used multi-color molds to match their branding, leading to strong customer reviews for comfort and response time.

10.2 What Our Customers Say

- “The custom rubber keypads fit perfectly and survived all our durability tests. The laser printing still looks new after heavy use.” – Product Manager, Industrial Controls

- “From prototype to full run, they hit every deadline and kept quality high. The backlit buttons have been a big selling point for us.” – Director, Consumer Electronics Brand

- “We loved how they could match our Pantone colors exactly. A true partner in product development.” – Owner, Specialty Gadget Manufacturer

These examples show how our role as a silicone rubber button manufacturer isn’t just about making parts — it’s about creating solutions tailored for everyday use, whether it’s for healthcare gear, cars, gaming, or industrial equipment.